Battery Pack Welding and Assembly

Laser Welding, Resistance Welding and Heavy Wire Bonding

We offer multiple technologies for welding battery packs. We are experts in metals joining technologies and have the experience required to specify the correct technology for the appropriate applications.

Laser Welding

- Non-contact process that minimizes heat affected zones

- Provides a clean and precise weld

- Highly customizable process that can handle different materials and sizes

- Ideal for low to medium volume production

Laser welding is an advanced joining technology that utilizes a high-powered laser beam to melt and fuse two or more workpieces together. The laser energy is precisely focused on the material, creating a small and concentrated heat source that quickly melts and solidifies the metal. Laser welding is used in a wide range of industries, from automotive and aerospace to medical and electronics, due to its ability to join thin and complex structures with high precision and accuracy. Additionally, laser welding is a non-contact process, minimizing the risk of contamination or damage to the materials.

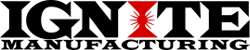

Resistance Welding

- Cost-effective and efficient process for high-volume production

- Strong and reliable bond between battery cells and busbars

- Does not require any filler materials

- Can handle thicker materials compared to laser welding

Resistance welding is a commonly used joining process in the manufacturing industry that involves applying pressure and an electric current to the workpieces to create a weld. The process utilizes the principle of Joule heating, which produces localized heat through electrical resistance, melting the workpieces and fusing them together. This technology is efficient, cost-effective, and produces strong, reliable welds in materials such as steel, nickel, aluminum, and copper. Different types of resistance welding techniques include spot welding, seam welding, and projection welding, each with its specific advantages and applications. Resistance welding is widely used in automotive, aerospace, and medical industries due to its high productivity and ability to produce consistent results.

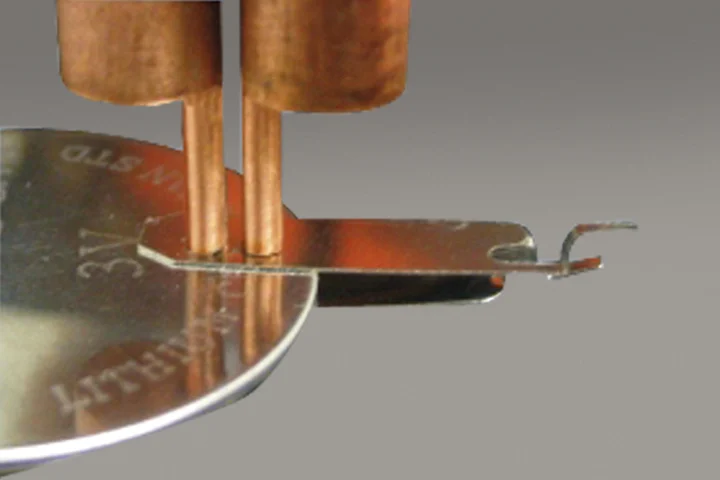

Wirebonding

- Ideal for small, lightweight batteries

- Provides a flexible and customizable process

- Offers a low-heat, low-stress process that minimizes damage to battery cells

- Ideal for low to medium volume production

Ultrasonic bonding is a wire bonding technique used in the semiconductor industry that combines both ultrasonic energy and localized heat to create a bond between a metal wire and a substrate. The process involves applying pressure and ultrasonic energy to the wire, which creates frictional heating that softens the wire and causes it to bond to the substrate. Wire bonding is commonly used for aluminum wire bonding applications and provides a high-quality bond with excellent mechanical strength and reliability. Additionally, the process is relatively fast, low-cost, and can be performed on a wide range of materials, making it a popular choice in the semiconductor industry.