Micro Welding Services

Manual R&D to Fully Automatic welding services available

At Ignite Manufacturing, we specialize in providing top-notch micro welding services to businesses across a variety of industries. Our team of experienced technicians and engineers is equipped with state-of-the-art equipment and a commitment to excellence that allows us to offer high-quality welding and bonding services for a range of applications.

Whether you need services for small or large scale projects, our team is dedicated to delivering precise and efficient results that meet your specific needs. We have a proven track record of successfully completing complex projects on time and on budget, making us the ideal partner for your micro welding needs.

In addition to our laser welding services, we also offer a range of value-added services to help streamline your production process. From design and engineering to finishing and assembly, our team can provide comprehensive solutions to meet all of your manufacturing needs.

If you're looking for a reliable partner for your laser welding needs, look no further than Ignite Manufacturing. Contact us today to learn more about our services and how we can help you achieve your production goals.

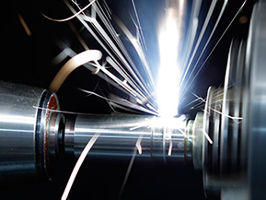

Laser welding

- Welding of thin and thick materials

- Welding of dissimilar materials

- Precision welding of intricate parts and components

- Welding of hard-to-reach areas

- Laser Marking and Etching

- Quick Turn/R&D

- No charge Design for Manufacturing (DFM) consulting

We use only the latest laser welding technology to ensure that our clients receive the best possible results. Our state-of-the-art equipment allows us to deliver precision welding with minimal heat input, ensuring that your materials remain strong and undamaged.

At Ignite Manufacturing, we understand that every project is unique, which is why we offer customized laser welding services tailored to your specific needs. Whether you need laser welding for prototyping, small-scale production runs, or large-scale manufacturing, we have the expertise and resources to deliver high-quality results that meet your requirements.

Resistance Welding

- Resistance Spot, Projection, Lap and Butt welding

- Hotbar

- Welding of thin and thick materials

- Welding of dissimilar materials

- Quick Turn/R&D

- No charge Design for Manufacturing (DFM) consulting

We understand that time is of the essence when it comes to manufacturing and especially R&D, which is why we offer fast turnaround times, timely delivery and free part evaluation. We are committed to ensuring that your project is completed on time and within budget.

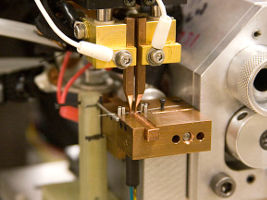

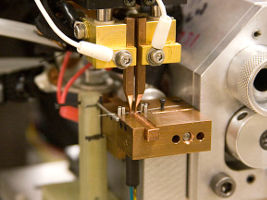

Wirebonding

- Ideal for small, lightweight batteries

- Provides a flexible and customizable process

- Offers a low-heat, low-stress process that minimizes damage to battery cells

- Ideal for low to medium volume production

Ultrasonic bonding is a wire bonding technique used in the semiconductor industry that combines both ultrasonic energy and localized heat to create a bond between a metal wire and a substrate. The process involves applying pressure and ultrasonic energy to the wire, which creates frictional heating that softens the wire and causes it to bond to the substrate. Wire bonding is commonly used for aluminum wire bonding applications and provides a high-quality bond with excellent mechanical strength and reliability. Additionally, the process is relatively fast, low-cost, and can be performed on a wide range of materials, making it a popular choice in the semiconductor industry.